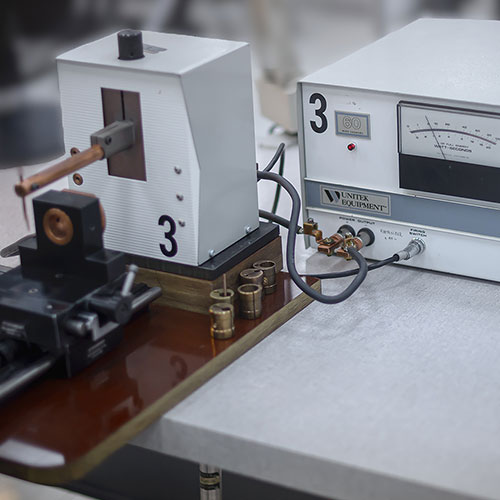

Induction Brazing

Induction brazing is a joining process that uses an alternating electromagnetic field to heat metal components and melt a filler material (brazing alloy), which then flows into the joint to create a strong bond. Unlike welding, the base metals are not melted; only the filler material melts and solidifies to form the joint. Because the heating is localized, rapid, and precisely controlled, induction brazing is well suited for joining dissimilar metals, delicate components, or assemblies that require minimal distortion. Ejay Filtration uses a NadCap approved induction brazing process that is in accordance with ANSI/AWS C3.5 Class “C” (formerly MIL-B-7883), which is a binding process for joining corrosion resistant components without any flux and is conducted within a hydrogen reducing atmosphere. This allows for a precise, strong and clean filter that you can rely on.

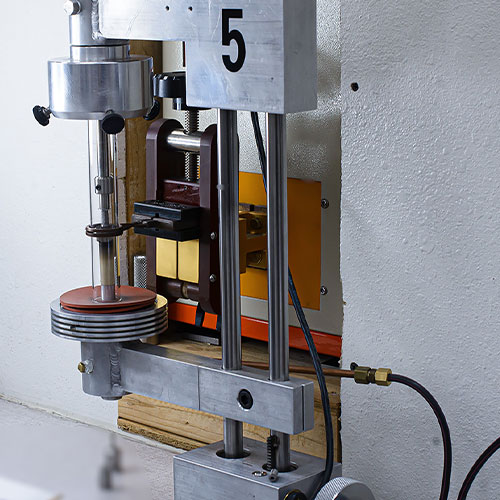

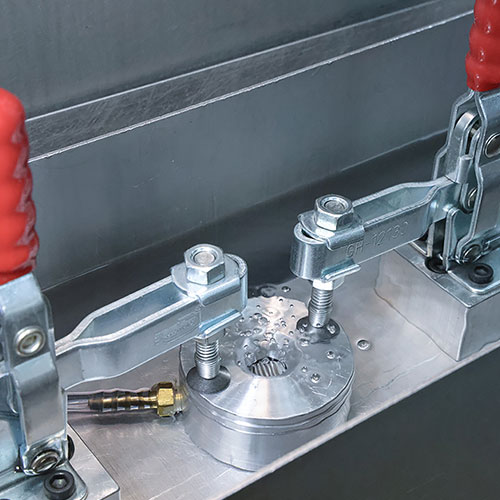

Resistance Welding

Resistance welding is a pressure-based joining process in which heat is generated by passing an electric current through metal pieces held together under pressure, causing localized melting and fusion without the need for filler materials. Two of the most common forms are spot welding, where sheets are joined at small contact points, and seam welding, which produces continuous, leak-tight welds along a joint. Because of its ability to create strong, precise, and reliable connections, without compromising the filtration surface area, Ejay Filtration uses resistance welding on almost every filter that goes out the door.

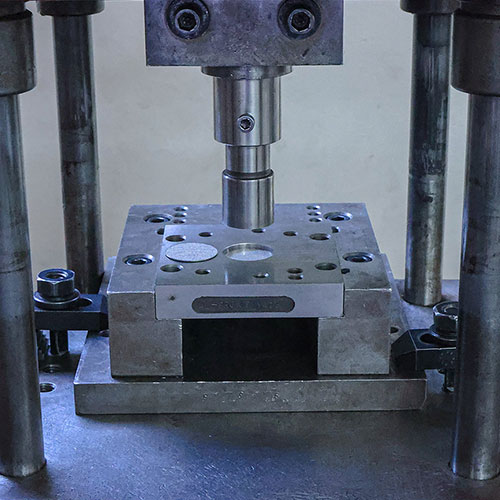

Precision Machining

Precision machining is a manufacturing process that involves the controlled removal of material from a workpiece using highly accurate machine tools to achieve exact dimensions, tight tolerances, and fine surface finishes. Ejay Filtration uses advanced top of the line equipment such as CNC (computer numerical control) mills, lathes, grinders, and EDM (electrical discharge machining) systems, which allow for repeatable, high-accuracy production. These machines and our highly trained machinists are essential for creating complex components that meet strict design specifications and tolerances.

Precision Manufacturing

Precision Manufacturing at Its Finest – At Ejay Filtration, every filter is crafted to order with uncompromising attention to detail. Our precision manufacturing process ensures each part reflects the latest design innovations, meets evolving industry and customer standards, and aligns with the strictest certification requirements. Backed by our highly skilled team and an impressive 99% on-time delivery rate, you can count on receiving a top-quality product exactly when you need it — every single time.

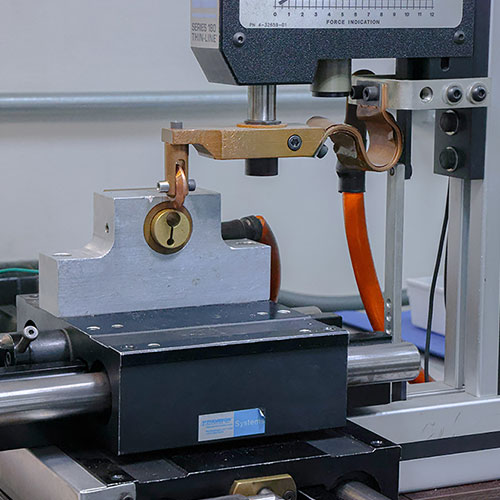

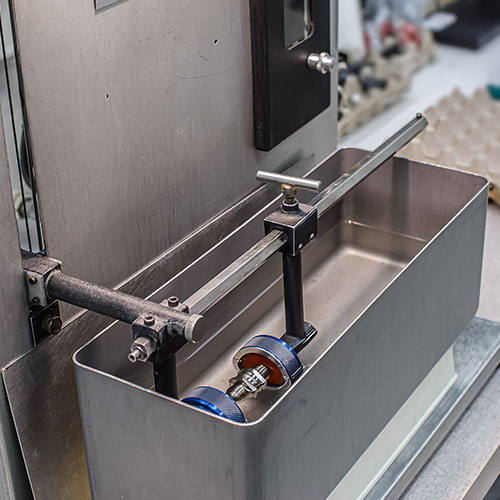

Bubble Point

Each filter is tested using our proprietary, custom-designed bubble point machine to ensure full compliance with the requirements outlined in ARP 901. This critical verification step confirms that the mesh meets the specified pore size and integrity standards necessary for reliable filtration performance. Our bubble point machine not only ensures that we meet mesh specifications, but also verifies that our critical manufacturing processes—resistance welding, brazing, and swagging—does not damage or compromise the mesh. By integrating this advanced quality control step into our production workflow, we maintain exceptional consistency across all products and demonstrate our commitment to delivering filters that meet or exceed both industry standards and customer expectations. Ejay Filtration’s goal is to ensure that every filter performs flawlessly, even in the most demanding applications.

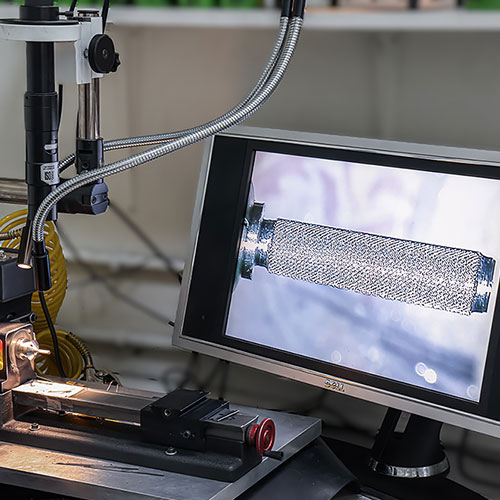

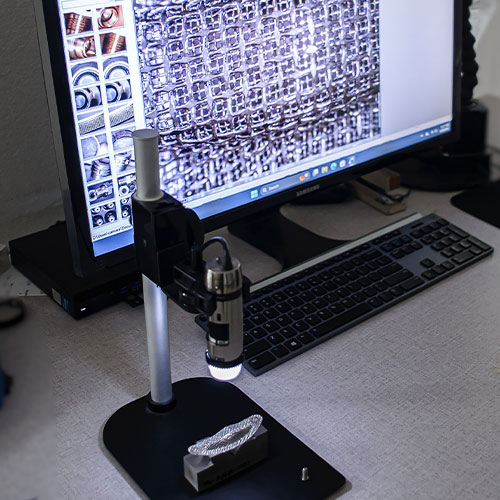

Inspection

With over 40 years of experience and a team of highly trained inspectors, we guarantee that every filter meets all specifications—whether it’s an industry standard or a Ejay Filtration Custom Design. Our inspectors meticulously verify that each filter is not only of the highest quality but also numerically and technically precise, ensuring flawless performance across all applications. This commitment to excellence is our standard, and we settle for nothing less than perfection.

Cleaning & Packaging

At Ejay Filtration, we understand that even the smallest contaminant can compromise the performance of a critical system. That’s why cleanliness isn’t just a requirement — it’s a core part of our manufacturing process. We use advanced Ultrasonic Cleaning with DI (de-ionized) Water, ensuring every component is thoroughly cleansed of any particles, oils, and residues that could impact functionality. Our cleaning process meets the AS4059 (formerly NAS-1638) standards and can achieve Class 4 cleanliness, ensuring that each product integrates seamlessly into your application and performs flawlessly from day one. This meticulous attention to cleanliness helps extend product life, protect downstream components, and ensure reliable operation under the most demanding conditions.